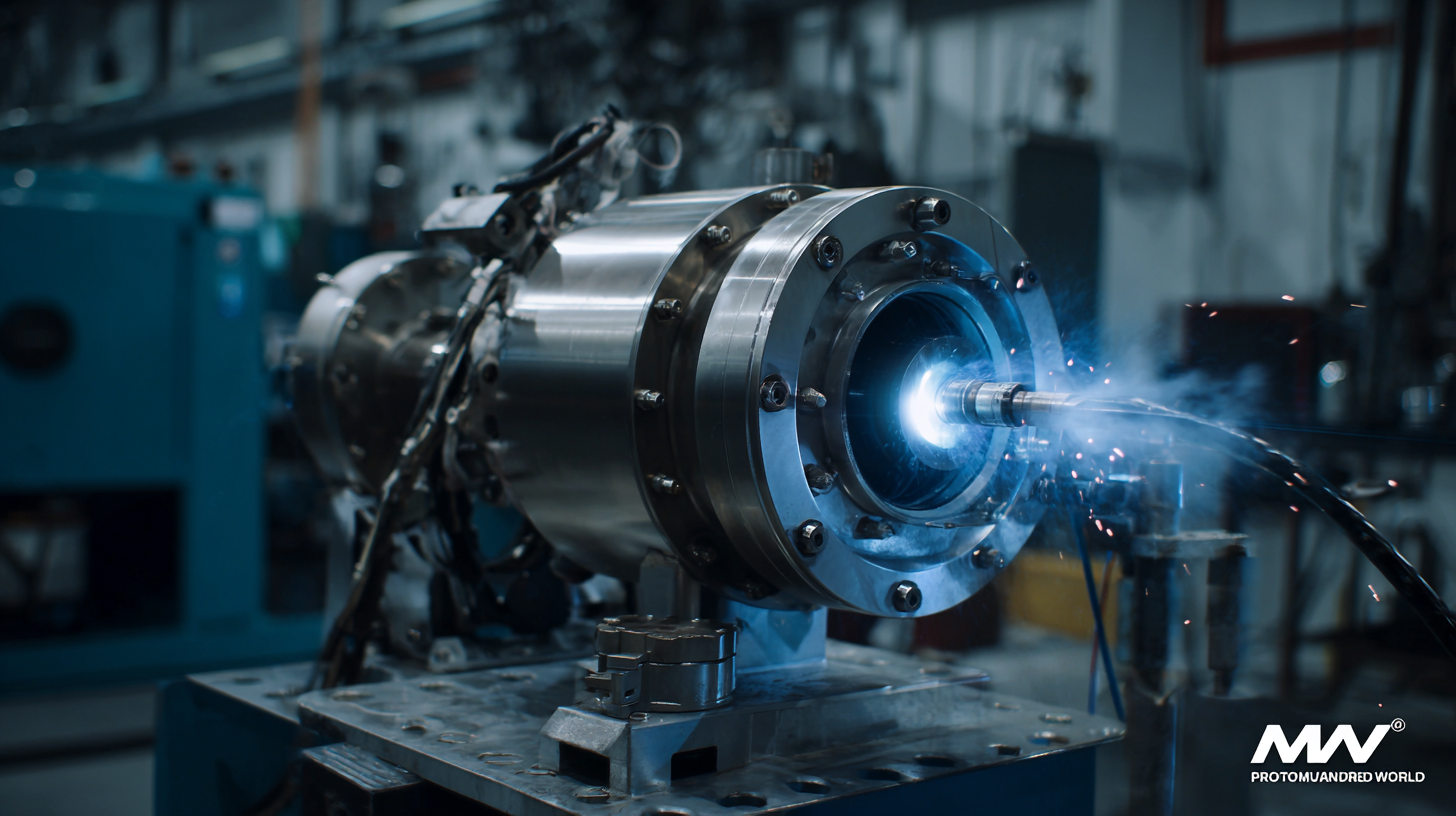

In the realm of advanced manufacturing and surface engineering, selecting the right Plasma Spraying Equipment is crucial for achieving optimal performance and quality in coatings. With a plethora of manufacturers and technologies available globally, navigating this landscape can be daunting. This blog aims to highlight the seven essential factors that should guide your decision-making process when choosing Plasma Spraying Equipment. From understanding the different types and solutions available to evaluating the reputation and credibility of manufacturers, we will provide insights that empower you to make informed choices. Whether you are a seasoned professional or new to the field, these key considerations will help ensure that your investment translates into enhanced operational efficiency and superior product quality. Join us as we explore what it takes to choose top-notch plasma spraying solutions that meet your specific needs.

When selecting plasma spraying equipment, several key factors can significantly impact performance and efficiency. First and foremost, the design and configuration of the plasma spray gun play a crucial role. According to a report by ResearchAndMarkets, the efficiency of plasma spray processes can vary greatly depending on the thermal characteristics of the gun and the quality of the plasma jet produced. Optimizing these parameters can lead to improved coating adhesion and reduced material waste, enhancing both quality and cost-effectiveness in industrial applications.

Another essential factor is the choice of materials for the spraying process. The type of powder used directly influences the properties of the final coating. The market for advanced ceramic materials is projected to reach approximately $7 billion by 2026, highlighting the growing importance of high-performance powders in plasma spraying. The particle size, morphology, and thermal conductivity of these powders can substantially affect melting efficiency and microstructure of the coatings, directly correlating with their durability and performance in demanding environments. Investing in high-quality materials is vital for maximizing the equipment's output and overall efficiency.

| Factor | Description | Impact on Performance | Efficiency Rating |

|---|---|---|---|

| Plasma Generator Type | Determines the stability and quality of the plasma jet. | High impact on coating quality. | 8/10 |

| Nozzle Design | Influences the velocity and direction of the spray. | Moderate impact on thickness distribution. | 7/10 |

| Cooling System | Maintains optimal operating temperatures for components. | Critical for consistent performance. | 9/10 |

| Material Feed System | Controls the consistency and rate of feed materials. | Directly affects coating adhesion and uniformity. | 8/10 |

| Operator Interface | User-friendly controls for adjustments and monitoring. | Improves ease of use and operational efficiency. | 7/10 |

| Energy Efficiency | Effectiveness in power consumption during operation. | Significant cost-saving potential. | 9/10 |

| Maintenance Requirements | Frequency and simplicity of maintenance tasks. | Affects downtime and operational reliability. | 8/10 |

When selecting plasma spraying machinery, there are several key specifications to consider to ensure optimal performance and results. First, you should evaluate the power output of the equipment. The wattage will impact the effectiveness of the spraying process, with higher power levels usually allowing for greater control over the spray characteristics. Additionally, consider the arc stability and the type of gas used in the spraying process, as these factors can influence the deposition rate and coating quality.

When selecting plasma spraying machinery, there are several key specifications to consider to ensure optimal performance and results. First, you should evaluate the power output of the equipment. The wattage will impact the effectiveness of the spraying process, with higher power levels usually allowing for greater control over the spray characteristics. Additionally, consider the arc stability and the type of gas used in the spraying process, as these factors can influence the deposition rate and coating quality.

Another crucial aspect is the versatility of the equipment. Look for machines that can handle various materials and coatings, as this will enhance your operational capabilities. The size and weight of the plasma spraying equipment are also important, especially if space and mobility are concerns in your workspace. Lastly, don’t overlook the importance of user interface and automation features, which can significantly enhance ease of operation and reduce training time for your staff. Evaluating these specifications will guide you to select the best plasma spraying machinery that matches your specific needs.

When selecting plasma spraying equipment, prioritizing essential safety features is paramount for ensuring reliable operations. First and foremost, the presence of robust safety interlocks is crucial. These interlocks prevent accidental startups and ensure that all components are properly engaged before the system can initiate spraying. This feature not only protects the operator but also minimizes risks associated with equipment malfunction.

Additionally, protective enclosures are a vital component in a safe plasma spraying environment. These enclosures act as barriers, shielding operators from harmful emissions and potential hazards produced during the spraying process. Effective ventilation systems must also be integrated into the equipment design to ensure that harmful fumes and particles are adequately extracted from the workspace, maintaining an optimal and safe air quality. By focusing on these critical safety features, manufacturers and operators can create a secure environment that promotes efficient and hazard-free plasma spraying operations.

When selecting plasma spraying equipment, evaluating the manufacturer's reputation and support services is paramount. A reputable manufacturer not only provides high-quality products but also ensures reliability through effective customer service. It's essential to investigate reviews and testimonials from previous clients, as these can reveal a lot about the company's commitment to excellence and after-sales support.

When selecting plasma spraying equipment, evaluating the manufacturer's reputation and support services is paramount. A reputable manufacturer not only provides high-quality products but also ensures reliability through effective customer service. It's essential to investigate reviews and testimonials from previous clients, as these can reveal a lot about the company's commitment to excellence and after-sales support.

Tip: Before finalizing a purchase, reach out to the manufacturer with questions about their equipment. Gauge their responsiveness and willingness to assist; this is often indicative of the support you can expect in the future.

Moreover, a manufacturer’s experience in the industry can significantly impact your choice. Companies with a long-standing presence are typically more adept at handling various challenges and offer robust warranties and service options. Always inquire about training, maintenance resources, and availability of spare parts.

Tip: Consider establishing a relationship with manufacturers who provide training sessions on how to effectively use their equipment. This can enhance the longevity of your investment and lead to better results in operations.

When it comes to selecting plasma spraying equipment, the balance between cost-effectiveness and quality is paramount. Businesses must consider their budget while ensuring they invest in machinery that delivers reliable and efficient performance. High-quality plasma spraying systems can often come with a hefty price tag, but it's essential to view this as an investment rather than merely an expense. The long-term benefits of durability and efficiency can outweigh the initial costs, leading to reduced operational downtime and lower maintenance expenses.

Additionally, organizations should conduct thorough market research to identify suppliers who offer competitive pricing without compromising quality. Comparing features and specifications of various plasma spraying systems can highlight differences that may justify price variations. Furthermore, consider the total cost of ownership, which encompasses not just the purchase price, but also operational costs, energy consumption, and potential training requirements for staff. By focusing on a holistic understanding of cost-effectiveness, companies can make informed decisions that align with their operational goals while ensuring they do not sacrifice quality in their plasma spraying equipment.

This chart illustrates the cost-effectiveness of various plasma spraying equipment options based on performance and price. The data reflects a comparison of quality ratings against their associated costs, allowing users to make informed decisions based on budget versus performance needs.

TradeManager

Teams

VKontakte