In the ever-evolving landscape of industrial applications, the demand for advanced technologies has led to significant innovations in various fields, particularly in the realm of Supersonic Spraying Equipment. This technology not only offers enhanced performance and efficiency but also presents unique solutions to meet diverse operational needs. As industries strive to improve their processes, understanding the comparative advantages of different Supersonic Spraying Equipment options becomes crucial. Whether you are involved in manufacturing, agriculture, or surface treatment, selecting the right equipment can make a substantial difference in productivity and quality. In this blog, we will delve into the innovative solutions available for Supersonic Spraying Equipment, providing a comprehensive comparison of available options and their unique features, so you can make an informed decision that aligns with your specific requirements.

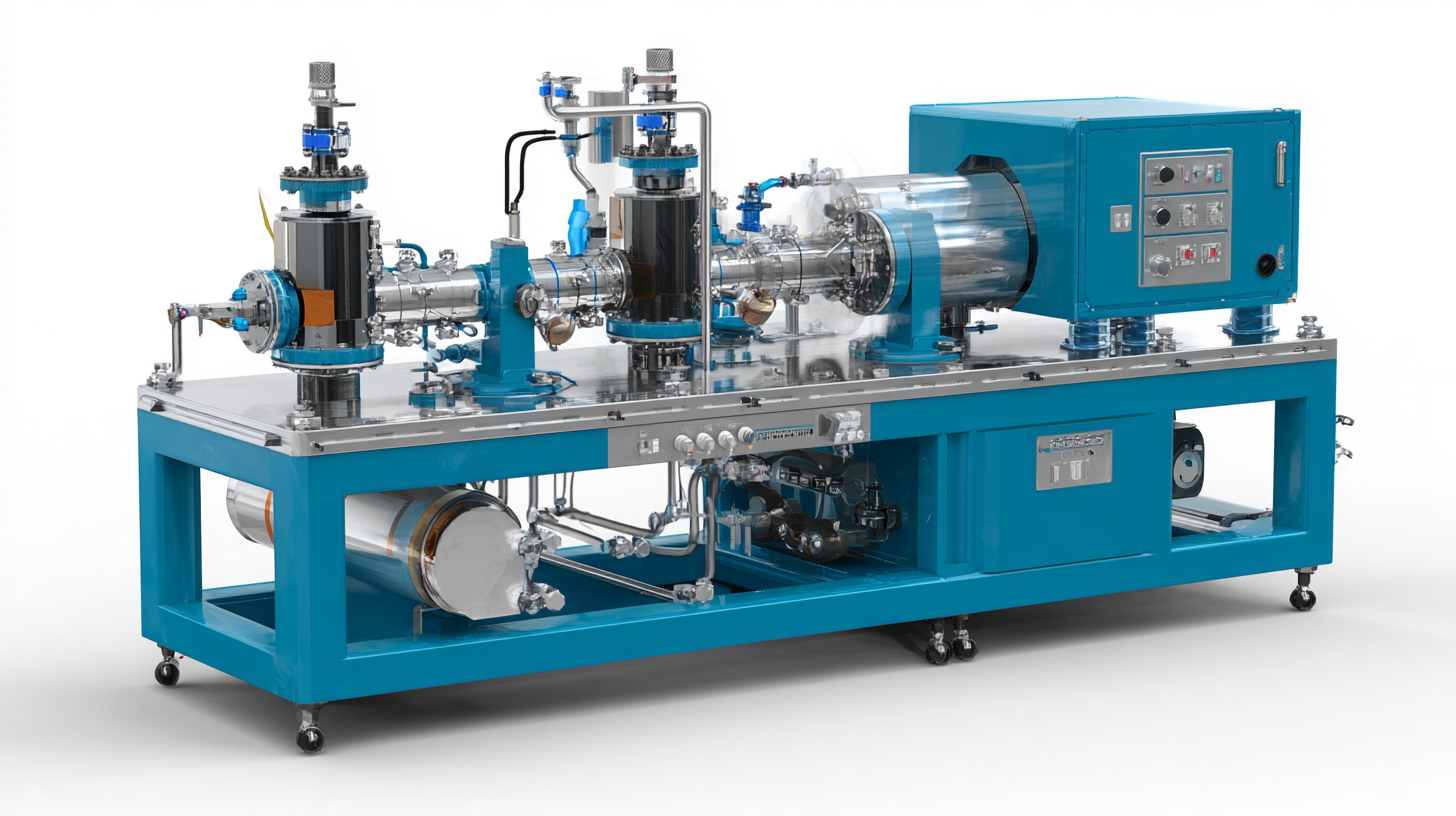

When exploring innovative solutions for supersonic spraying equipment, understanding the technical specifications is crucial for optimizing performance. Supersonic spraying, a technique that utilizes high velocities to atomize materials, requires equipment capable of withstanding extreme conditions. Key specifications to consider include the nozzle design, which plays a vital role in determining spray pattern and particle size. Advanced nozzle geometries can significantly enhance material adhesion and coat uniformity, making them essential for applications in automotive, aerospace, and even biomedical sectors.

Additionally, evaluating the power output and operational temperature capacity of the equipment is fundamental. Equipment must be engineered to maintain stable performance under varying environmental conditions. For instance, the energy impulse generated during the spraying process must be sufficient to achieve the desired coating thickness without compromising material integrity. Manufacturers are increasingly integrating smart technology into their supersonic spraying systems, allowing for real-time monitoring and adjustments to maintain optimal performance. Understanding these specifications will ultimately lead to more efficient processes and superior product quality.

Innovative spraying technologies are revolutionizing precision agriculture, offering numerous key features and advantages that can enhance crop protection while promoting sustainability. One significant advancement is AI-powered spot spraying, which can decrease herbicide usage by up to 90% compared to traditional blanket spraying methods. This dramatic reduction not only conserves resources but also minimizes environmental impact, aligning with the industry's shift towards more sustainable practices.

Moreover, the integration of GPS and automation in modern spraying equipment has improved operational efficiency. By 2025, it is anticipated that over 60% of new tractors will incorporate automatic steering systems specifically designed for precision agriculture. These innovations not only streamline the spraying process but also enable farmers to optimize their inputs effectively, leading to improved yield and profit margins.

Moreover, the integration of GPS and automation in modern spraying equipment has improved operational efficiency. By 2025, it is anticipated that over 60% of new tractors will incorporate automatic steering systems specifically designed for precision agriculture. These innovations not only streamline the spraying process but also enable farmers to optimize their inputs effectively, leading to improved yield and profit margins.

Additionally, drone technology has emerged as a game-changer in agricultural spraying. The use of drones for applying pesticides and fertilizers increases accessibility and precision in hard-to-reach areas of farmland. The ability to operate under government regulations while harnessing advanced AI, sensors, and smart data ensures that farmers can adopt these technologies with confidence. Collectively, these innovative solutions are paving the way for a more efficient and sustainable future in agriculture.

Operating supersonic spraying systems can seem daunting at first, but with a step-by-step approach, you can master the technique efficiently. Begin by familiarizing yourself with the components of the equipment, such as the nozzle, pressure regulator, and feed system. Ensuring you understand how each part functions will not only enhance your operation but also increase the longevity of your equipment.

Tip: Before starting, always check for any blockages in the nozzle. A clean nozzle ensures a consistent spray pattern and prevents uneven application, which is crucial for achieving the best results.

Next, set up the machine according to manufacturer specifications. This includes adjusting the pressure settings and preparing your material for spraying. Experiment with different settings to find the optimal speed and pressure for your specific application. Remember to wear appropriate safety gear to protect yourself from fine particles that may be ejected during the spraying process.

Tip: Keep a log of your settings and results for future reference. This can help you identify what works best for different projects and save time when starting on new tasks.

| Dimension | Description | Value |

|---|---|---|

| Nozzle Type | Type of nozzle used for spraying | Dual-Fluid Nozzle |

| Operating Pressure | Pressure required for optimal operation | 3000 PSI |

| Spray Angle | Angle of spray output | 120 Degrees |

| Flow Rate | Amount of fluid dispensed per minute | 5 Liters/min |

| Materials Compatible | Types of materials that can be sprayed | Water-based, Solvent-based |

| Electrical Requirements | Power supply needed for operation | 220V AC, 50Hz |

Maintaining your supersonic spraying equipment is crucial to ensure it operates at peak performance. Regular maintenance not only extends the lifespan of your equipment but also enhances efficiency, ultimately saving you both time and money. Start with routine inspections; check for any signs of wear and tear, ensuring that all components are functioning correctly. Clean the nozzles and filters regularly to prevent clogging, which can significantly affect spray quality and consistency.

Another important tip is to monitor the fluid levels and replace worn or damaged hoses immediately. Using the correct type of fluid is essential for optimal performance, as it can greatly influence the spraying output and quality. Furthermore, scheduling professional servicing at least once a year can help identify potential issues before they escalate. By implementing these maintenance practices, you can ensure your supersonic spraying equipment delivers outstanding results consistently, meeting all your spraying needs effectively.

Supersonic spraying technology has emerged as a game-changer in various industries, particularly when compared to traditional spraying methods. One of the most significant advantages of supersonic spraying is its ability to produce finer atomization. This results in a more uniform coating with less overspray, enhancing material efficiency and reducing waste. Traditional methods often struggle with achieving the same level of precision, leading to more rework and higher overall material costs.

**Tip:** When transitioning to supersonic spraying, ensure that your equipment is calibrated correctly to optimize the spray pattern and minimize material loss. A well-calibrated system will not only improve efficiency but will also enhance the finish quality of your products.

Another key difference lies in the speed of application. Supersonic spraying can significantly reduce the time required for coating applications, thanks to its high-velocity spray technique. In contrast, traditional methods can be labor-intensive and slow, which might hinder production timelines. This rapid application can boost productivity without compromising the quality of the finish.

**Tip:** Consider regular training sessions for your team on the latest supersonic spraying techniques. Keeping your staff updated on new technologies can result in better operational efficiency and more innovative uses of the equipment.

TradeManager

Teams

VKontakte