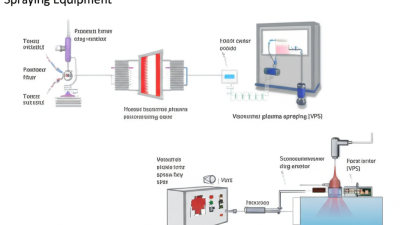

Plasma spraying equipment has emerged as a pivotal technology in various industrial applications, owing to its unique ability to create high-performance coatings that enhance the durability and functionality of materials. This blog aims to explore the distinct features of different plasma spraying equipment, delving into their mechanisms, capabilities, and the specific applications they serve.

Plasma spraying equipment has emerged as a pivotal technology in various industrial applications, owing to its unique ability to create high-performance coatings that enhance the durability and functionality of materials. This blog aims to explore the distinct features of different plasma spraying equipment, delving into their mechanisms, capabilities, and the specific applications they serve.

By examining these technologies, we will uncover the top strategies for optimizing their use in industries such as aerospace, automotive, and biomedical engineering. The versatility of plasma spraying equipment not only allows for the deposition of a wide range of materials, including metals, ceramics, and polymers, but also enables the customization of coating properties to meet specific performance requirements.

Join us on this journey as we analyze how advancements in plasma spraying technology contribute to innovation and efficiency across various fields.

The certification and licensing of plasma spraying equipment play a crucial role in ensuring quality and safety in both domestic and international markets. With the rise of precision agriculture and advanced manufacturing, compliance with import and export regulations has become increasingly significant. For instance, as the agricultural sector in regions like Adamawa State benefits from training in pesticide management, equipment used for applying these chemicals must meet stringent standards to enhance agricultural exports. This highlights the need for extensive knowledge of import/export procedures, as unauthorized or unverified equipment can lead to violations of trade regulations and potential penalties.

Moreover, industries involved in plasma spraying must navigate specific certification requirements. The implementation of frameworks such as the TAPA charter emphasizes the importance of having appropriate pest control measures in place, especially when exporting machinery. A recent report indicates that adherence to certification not only improves market access but also boosts competitiveness. Businesses that ensure their plasma spraying equipment meets international standards can leverage this compliance to secure better contracts globally, ultimately contributing to higher export volumes and enhanced reputation in the industry.

In the realm of plasma spraying equipment, compliance with key regulations and standards is crucial for ensuring safety, efficacy, and environmental responsibility. The plasma spraying industry is governed by various regulations that dictate the quality and performance of coatings used in multiple applications, from aerospace to biomedical sectors. These standards not only help maintain consistency in product quality but also push for innovative practices that can enhance the environmental sustainability of the processes involved.

One notable area of impact is the thermal spray coatings market, which is projected to grow significantly in the coming years. European regulations are steering the industry towards safer and more efficient thermal spraying techniques, focusing on minimizing waste and using environmentally friendly materials. Additionally, the integration of advancements in cold plasma technology is transforming food processing, where food safety regulations are becoming increasingly stringent. This technology offers a non-thermal method that effectively reduces microbial contamination while preserving nutritional quality, showcasing the need for adaptable equipment that meets evolving standards in various industries.

| Equipment Type | Unique Features | Applications | Key Regulations/Standards |

|---|---|---|---|

| Atmospheric Plasma Sprayer | Uses atmospheric air as plasma gas, cost-effective, versatile | Coating metals, ceramics, and polymers | ISO 13485, ASTM C633 |

| Vacuum Plasma Sprayer | Operates in a vacuum chamber, high-quality coatings | Aerospace components, electronics | ASTM B733, EN 14530 |

| Low Pressure Plasma Sprayer | Low pressure enhances adhesion, precise control | Biomedical devices, decorative coatings | ISO 9001, ASTM E285 |

| Plasma Transferred Arc Sprayer | High energy density, thick coatings | Welding, repairing heavy machinery | AWS D1.1, ASME BPVC |

| Cold Spray Equipment | Uses kinetic energy, minimal thermal impact | Restoration of parts, additive manufacturing | ISO 24030, ASTM B787 |

Obtaining certification for plasma spraying equipment can be a daunting task due to various challenges that manufacturers and operators face. One of the primary hurdles is navigating the complex regulatory landscape, which often varies by region. Different certifications may be required depending on the application, necessitating a deep understanding of local and international standards. This lack of clarity can lead to delays in the certification process, as companies may need to continuously adapt their equipment or procedures to meet changing regulations.

Tip: To streamline the certification process, consider investing in a compliance specialist familiar with plasma spraying. This expert can provide valuable insights into the required standards and help mitigate the risks of non-compliance.

Another common challenge is ensuring the equipment meets rigorous performance and safety criteria. Testing the plasma spraying systems under extreme conditions is essential, yet it demands significant resources and time. Manufacturers often find themselves needing to invest in advanced testing facilities or partner with certified labs to achieve the necessary validation.

Tip: Regularly schedule maintenance and upgrades for your equipment to ensure it consistently meets performance benchmarks. This proactive approach not only aids in certification but also enhances the overall reliability and longevity of the equipment.

The global market for plasma spraying equipment has been significantly influenced by various trends affecting certification processes. As industries increasingly emphasize quality and performance, the demand for certified equipment has surged. According to a recent report by MarketsandMarkets, the plasma spraying market is projected to grow from USD 1.6 billion in 2023 to USD 2.4 billion by 2028, at a CAGR of 8.5%. This growth highlights the necessity for adherence to stringent certification standards to ensure reliability and safety in applications like aerospace and automotive sectors, where the performance of plasma-sprayed coatings is critical.

Regulatory changes and international standards play a crucial role in shaping the certification landscape. Manufacturers are compelled to align their products with ISO and ASTM standards to cater to the expanding global market. For example, the recent revisions in ISO 9001 have introduced new benchmarks for quality assurance that manufacturers must meet.

Tip: Companies looking to enter the plasma spraying market should prioritize compliance with relevant certifications, as this will not only enhance their credibility but also allow access to new markets. Additionally, staying updated with regulatory changes can provide a competitive edge, ensuring products meet the latest industry standards. Investing in training for staff on certification processes can greatly reduce the risk of non-compliance.

When it comes to exporting plasma spraying equipment, compliance with international standards is paramount. Manufacturers must familiarize themselves with the regulations set forth by organizations such as ISO and ASTM. Understanding these standards not only facilitates smoother international transactions but also ensures product quality and safety. To achieve compliance, it’s essential for companies to implement rigorous quality control measures throughout the production process, from sourcing materials to final testing before shipment.

In addition to adhering to established standards, companies should also prioritize transparency in their export documentation. This includes providing thorough technical specifications, safety certifications, and any relevant compliance evidence. Engaging with experienced customs brokers can further streamline the export process by helping navigate complex regulations. By adopting these best practices, manufacturers can minimize the risk of regulatory penalties and build a solid reputation in the global market for plasma spraying equipment.

TradeManager

Teams

VKontakte